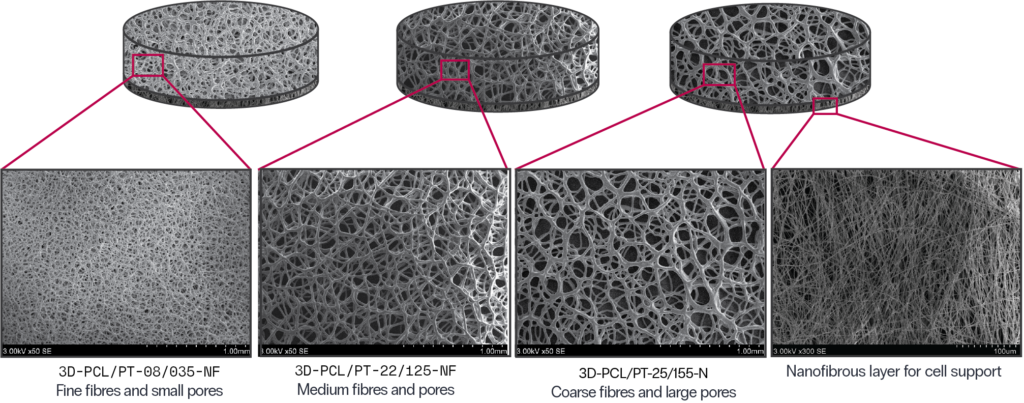

3D cell culture scaffolds designed as hard polymer fibre constructs:

Such design provides a favourable environment for cell attachment and proliferation. The round fibre and pore morphology follows a random structure of natural extracellular matrix (as compared to straight/aligned fibre and filament structures). Large pores allow for an efficient cell distribution throughout the entire scaffold height.

Specifications:

Construction: 3D, 2-layer (nanofibre bottom)

Basis polymer: PCL, plasma-treated

SKU: 3D-PCL/PT-08/035-NF

Fibre diameter (mean) 8 μm

Pore diameter (mean) 35 μm

SKU: 3D-PCL/PT-22/125-NF

Fibre diameter (mean) 22 μm

Pore diameter (mean) 125 μm

SKU: 3D-PCL/PT-25/155-NF

Fibre diameter (mean) 25 μm

Pore diameter (mean) 155 μm

Features

• Tunable morphology

• Cut-to-size

• Easy imaging

• UV-sterilized and ready to use

• Compatible with most current 2D assays

Applications

• Drug screening

• Environmental cytotoxicity

• Tissue engineering

• Organ-on-chip models

Modifications

• Wetting properties

• Cold plasma surface activation

• Attachment of functional molecules (growth factors)

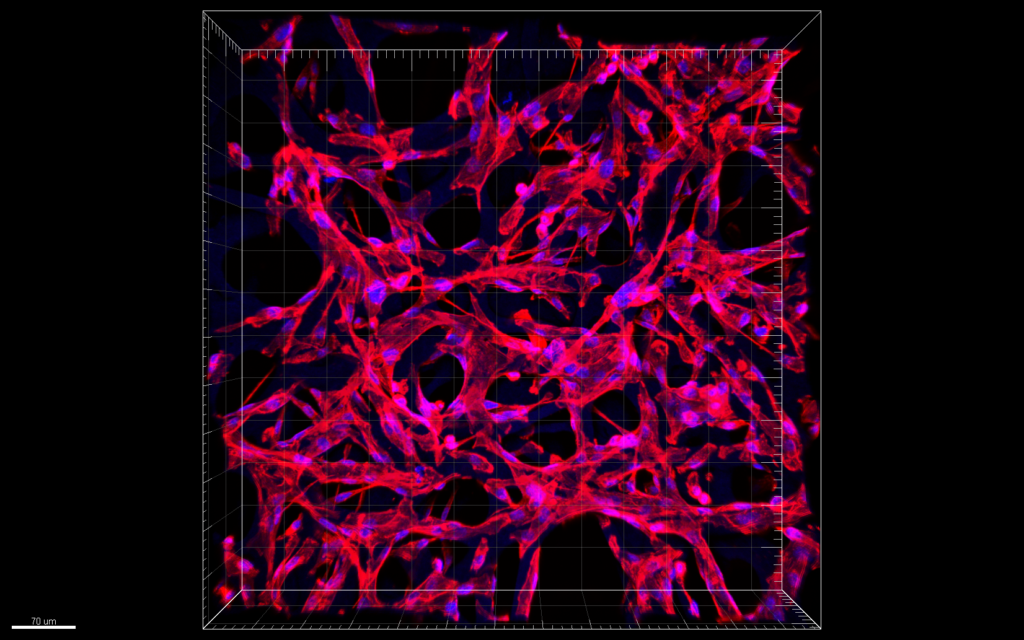

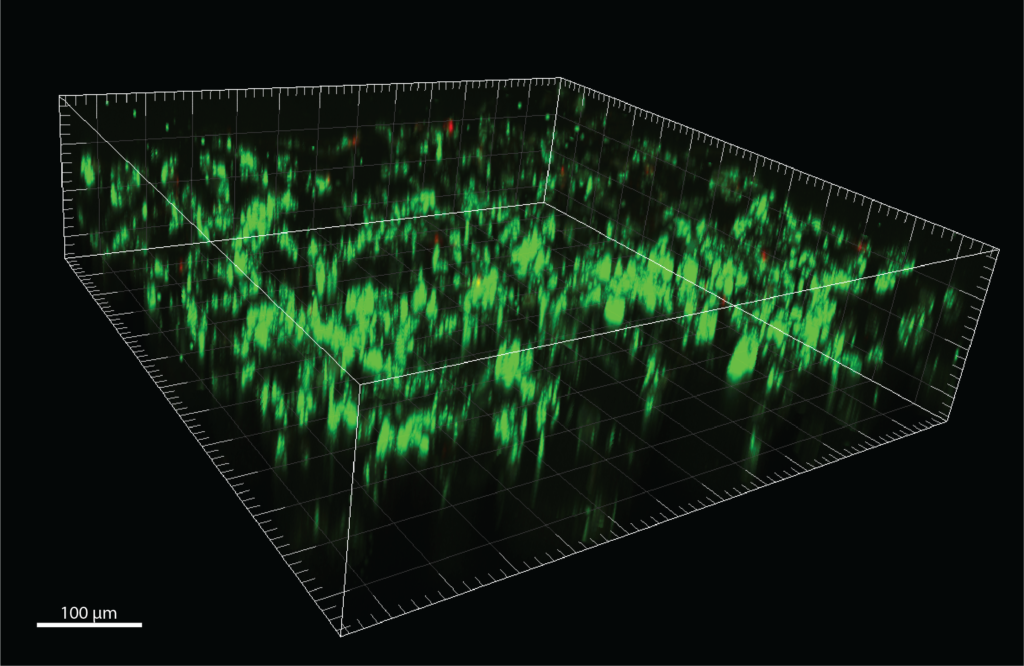

Confocal microscopy images of MDA-MB-231 cells in scaffold

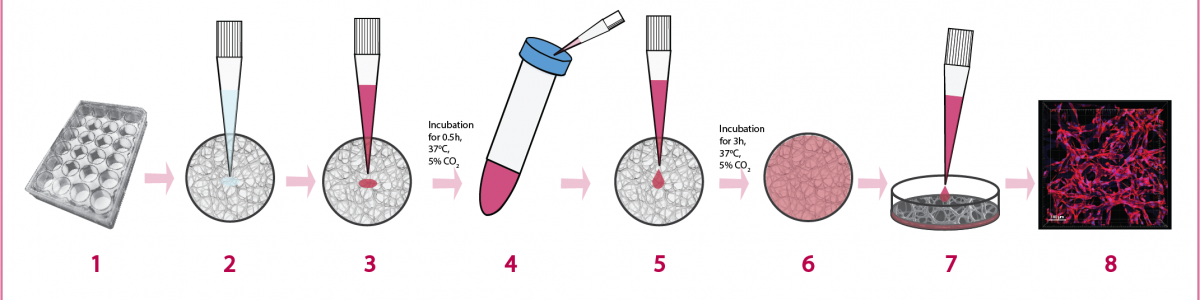

Common protocols for 2D cell cultures can also be adapted when working with 3D cell cultures.

Scaffolds are compatible with both assays.

Recent application: https://doi.org/10.1016/j.bej.2022.108531

Ciuzas D., Krugly, E., Petrikaite, V. Fibrous 3D printed poly(ɛ)caprolactone tissue engineering scaffold for in vitro cell models. Biochemical Engineering Journal, Volume 185, July 2022, 108531