Technology

Our core technology combines solvent-free and solvent-based electrospinning processes with additive manufacturing (3D printing). 3Df printer prints many nano and micro filaments instead of a single filament. Such modification of traditional 3D printing technique introduces high-voltage electrostatic field which turns polymer filament into nano and micro sized fibres and pores.

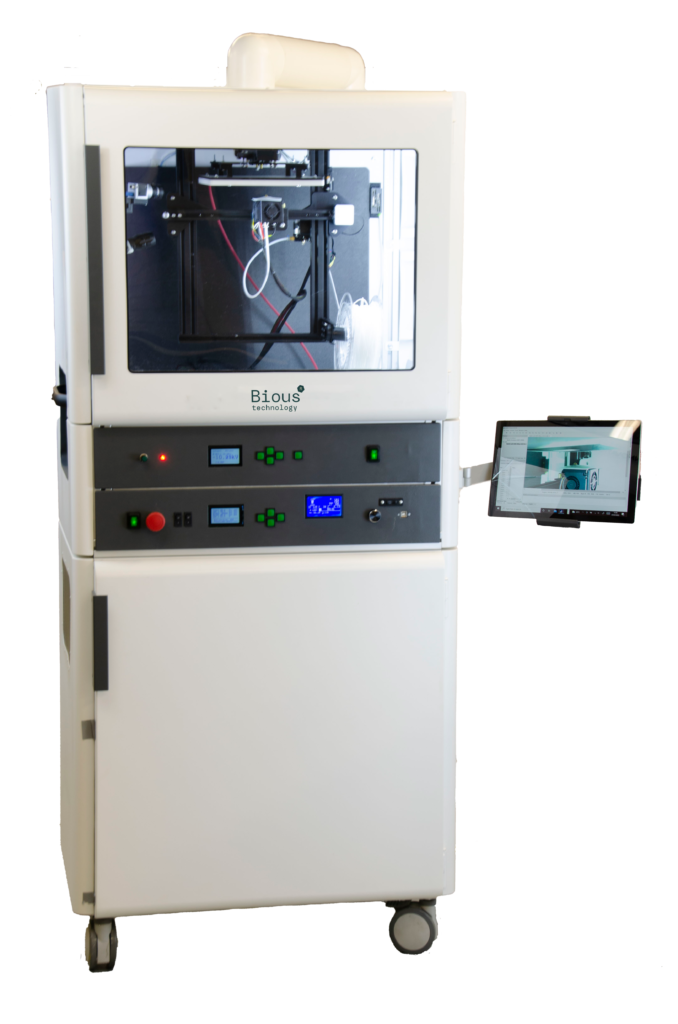

These printers are fully customized to users requirements and are comprised of FDM unit, high voltage unit and climate control unit, packed in a compact and mobile installation. A combination of analogue and digital controls allow of continuous real time adjustment of polymer feed rate, voltage, travel speed, tip-to-collector distance, indoor temperature and humidity.

The FDM unit features:

– upside-down design, minimizing the probability of matrix defects due to dripping.

– filament based spinning, where only a small portion of filament is heated thus minimizing polymer degradation and related toxicity of fibres.

Unit Specifications:

Model: 3Df-01C

Printing base: FDM printer (filament based, printing area 250×250 mm)

Voltage: 5-20 kV

Tip-to-collector dist.: 5-30 mm

Polymer feed rate: 5-15 mg/s

Polymer melting T: 100-270 oC

Polymer filament diam.: 1.75-3.0 mm

Inside T, climate controlled: 20-35 oC

Inside RH, climate controlled: 30-80 %

Dimensions LxWxH: 830x620x1840 mm (w climate control unit)

Unit weight (w/o climate control): 65 kg

Unit weight (w/climate control): 105 kg